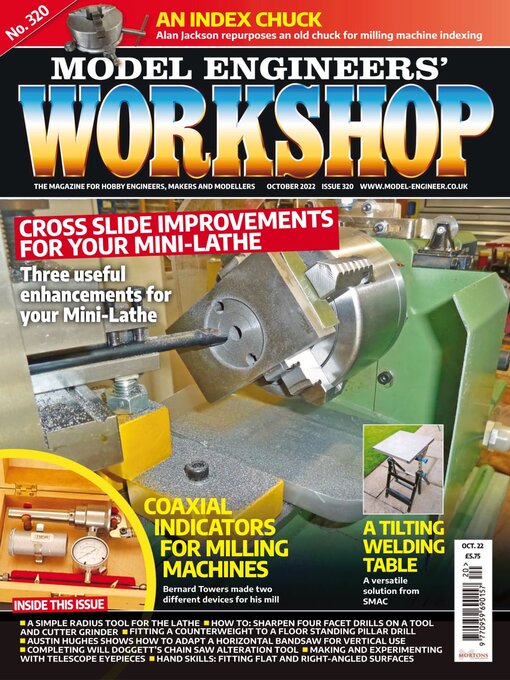

Model Engineers' Workshop is the ideal workshop companion for all hobby engineers. Model Engineers' Workshop shines a spotlight on the tools and techniques used by model makers, light engineers, restorers and customisers and those who like making and modding their own tools. You'll find readers' tips, reviews of workshop equipment as well as articles on restoring old tools and making your own as well as the latest new technologies, techniques and materials. Model Engineers' Workshop magazine publishes 12 great issues a year.

Model Engineers' Workshop

On the Editor’s Bench

A vintage ‘Lathe Tailstock Tool Holder’

Elevating a Horizontal Bandsaw • After many years of use, and various bits of tweaking, Austin Hughes’ entry-level CY90 bandsaw from Warco has paid for itself many times over, so he decided to see if it could be further enhanced by being adapted for use as a vertical saw, and thereby be made suitable for sheet materials

Hand fitting methods for flat and right-angle faces • These articles by Geometer (Ian Bradley) were written about half a century ago. While they contain much good advice, they also contain references to things that are out of date or describe practices or materials that we would not use today either because much better ways are available or for safety reasons. In particular, never use abrasive cloth on a lathe without a backing board. These articles are offered for their historic interest and because they may inspire more modern approaches as well as reminding us how our hobby was practised in the past.

Drill Grinding on a Worden • Howard Lewis shares his experiences of improving this popular cutter grinder for drill sharpening with guidance on making your own accessories.

In our Next Issue

Scribe a line • YOUR CHANCE TO TALK TO US!

Radius Tool for Topslide • Peter Peters describes a simple but useful accessory

Making Eyepieces in the Workshop • Stargazer experiments with some simple optics.

Easy extraction of shaft keys

A Tale of Two Indicators • A coaxial indicator is fitted in the spindle of a milling machine and used to accurately align it with workpieces. Bernard Towers explains how he made two of his own to overcome issues with the size of commercial types.

An Indexing Chuck • Alan Jackson made a useful accessory from an old lathe chuck.

Rust • Depending on your workshop, rust may only be something to you see on objects brought into the shop, or it may be a constant enemy you battle with. A dry, ventilated but well insulated workshop is unlikely to have major rust issues, but if you have to locate your workshop in a damp cellar, leaky shed or even share garage space with a damp car then you may have problems.

A Portable Welding Bench • SMAC makes a tilting workshop bench from found materials

NEXT ISSUE

A Chain Alteration Tool • Will Doggett makes some savings with a home made rotary riveting tool – part 3

On the Wire • NEWS from the World of Hobby Engineering

Pillar Drill Table Counterweight • Mike Philpotts designs and installs a counterweight system for a Medding’s floor standing pedestal drill table

Modifying my Mini Lathe Part 2 • Continuing from his article in MEW 317, Geoff Andrews finds that using the slotted table from a vertical slide as a boring table on a mini lathe is fairly straightforward.

Jan 01 2026

Jan 01 2026

Dec 01 2025

Dec 01 2025

Nov 01 2025

Nov 01 2025

Oct 01 2025

Oct 01 2025

Sep 01 2025

Sep 01 2025

Aug 01 2025

Aug 01 2025

Jul 01 2025

Jul 01 2025

Jun 01 2025

Jun 01 2025

May 01 2025

May 01 2025

Apr 01 2025

Apr 01 2025

Mar 01 2025

Mar 01 2025

Feb 01 2025

Feb 01 2025

Jan 01 2025

Jan 01 2025

Dec 01 2024

Dec 01 2024

Nov 01 2024

Nov 01 2024

Oct 01 2024

Oct 01 2024

Sep 01 2024

Sep 01 2024

Aug 01 2024

Aug 01 2024

Jul 01 2024

Jul 01 2024

Jun 01 2024

Jun 01 2024

May 01 2024

May 01 2024

Apr 01 2024

Apr 01 2024

Mar 01 2024

Mar 01 2024

Feb 01 2024

Feb 01 2024